This is an exquisite motor – a substantial inertia of 2.1 Joules at 1500rpm and super finely balanced with <10 milligram two plane adjustments to the rotor. This is evident with small drill holes – 1.5mm diameter and 1mm deep (or greater) to remove very small amounts of mass.

First plots are mains 220V 50Hz with 1uF run capacitor. Peaks at 25Hz (rotational speed of rotor) and 100Hz (supply x 2). As mentioned in the summary, the ripple is nearly all the harmonics of 25Hz and appeared to be a vertical issue – resetting the thrust pad location as it was slightly offset from centre fixed this.

.

Next are plots at 50Hz using the tuned phase supply – as expected the 100Hz peak is reduced – by 8dB and the ripple is gone.

.

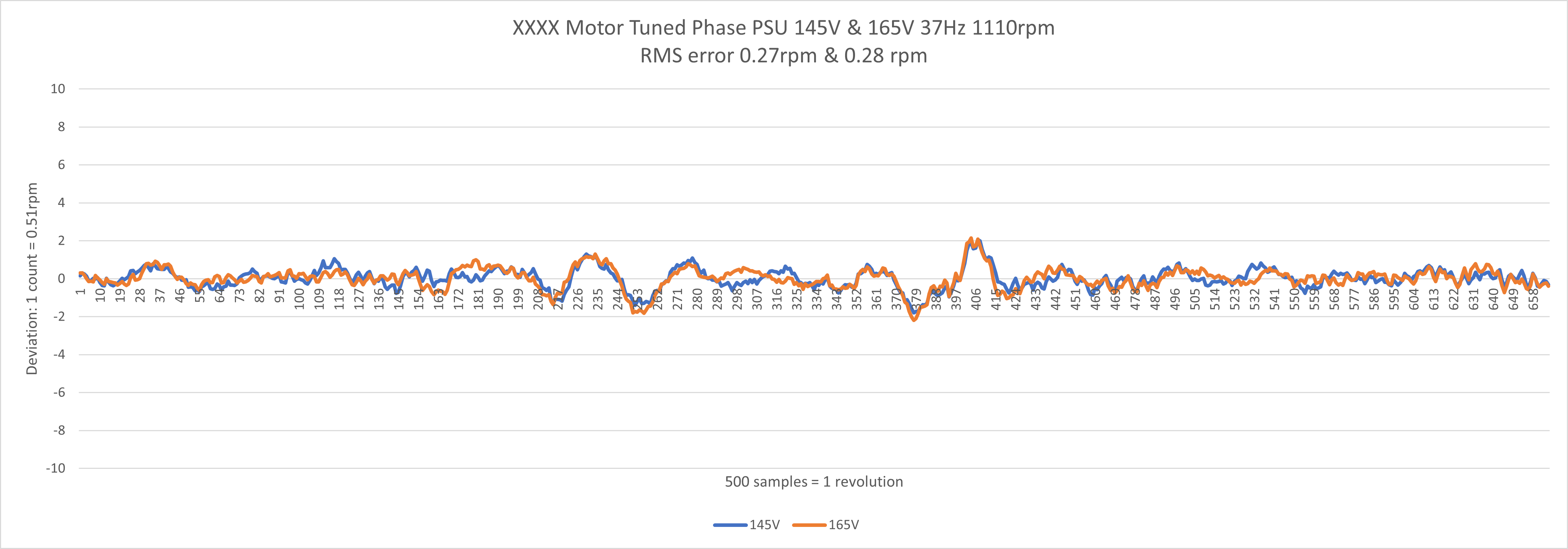

The following plots are at 37Hz – this is to show what would happen if 37Hz -1110 rpm was used for 33rpm and 50Hz – 1500rpm for 45rpm. The voltage is reduced accordingly.

.

Included below is a new plot where the lightweight universal 3D printed mounting plate touches the frame – this is to illustrate what controls can be implemented to reduce the residual vibration. The only residual vibration above the noise floor are small -55 to -60dB peaks at 222, 296 and 370Hz. I will revisit this once all the motor testing is done to determine a solution that potentially gives no vibration above the noise floor…..

.

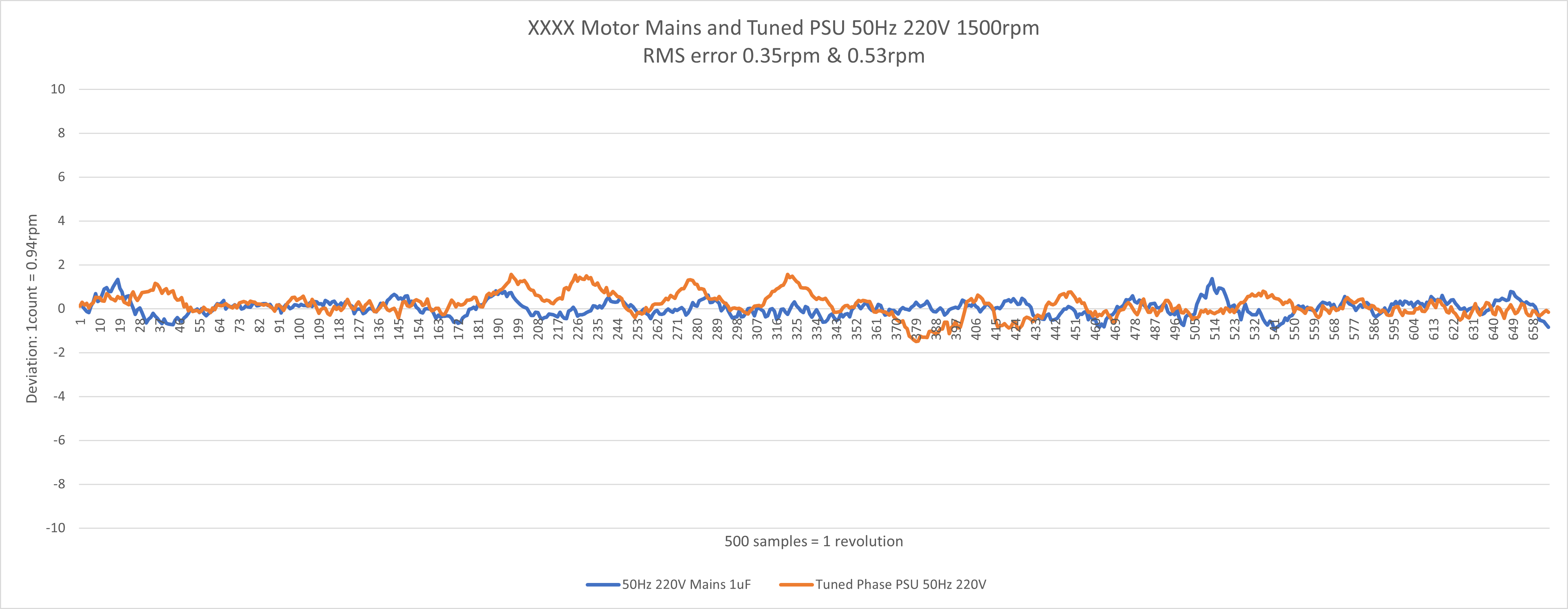

Speed Variation plots. Very consistent rotation speed…..and is the best to date. This is approaching the noise floor/resolution of the 50nS counter approach.

.

.